Recherche & collaboration

Qu’est-ce qui nous rend unique ?

SuperGrid Institute doit son succès aux personnes qui composent nos différents départements de recherche. Nos équipes viennent d’horizons divers, tant industriels qu’universitaires, et la richesse de leur expérience et de leurs compétences rend l’Institut unique.

Chaque personne apporte une expertise spécifique et ce vivier de connaissances offre aux spécialistes de différents domaines la possibilité de collaborer sur des solutions innovantes pour résoudre des problèmes techniques.

L’Institut bénéficie d’étroites relations de collaboration avec des acteurs de l’industrie et des institutions académiques. Alors que les forces complémentaires de nos partenaires apportent des éclairages et des approches innovantes aux défis techniques, nous développons nos départements de recherche en toute indépendance. Des investissements conjoints publics-privés et des projets de collaboration financent le travail.

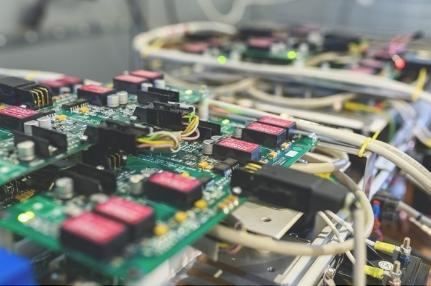

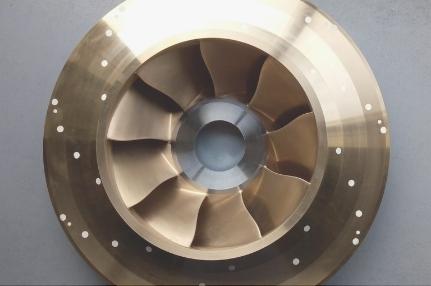

Les installations de recherche, les plateformes de test et les laboratoires de pointe de SuperGrid Institute sur les sites de Villeurbanne et de Grenoble sont la clé du succès de nos départements de recherche.

Nos dernières publications scientifiques

Compliance of a cable-based protection strategy for OHL grids: Analysis and remediation

This paper points out the challenges to overcome when applying a protection strategy based on a non-selective fault clearing philosophy without DC reactors to an overhead line based multi-terminal DC grid.

A novel single-ended fault identification algorithm for full selective protection strategy

We propose a parametric single-ended fault identification algorithm to be used in full selective protection strategy.

Characterization of Partial Discharges Initiated by Protrusion in HVDC Coaxial Geometry

This paper aims at the detection and characterization of partial discharges (PD) in GIS under HVDC constraints in the presence of a protrusion/metallic particle on the high voltage conductor.