High Voltage Substation Equipment

“In the High Voltage Substation Equipment research department, we respond to the constraints of DC networks whilst respecting the environment.”

Marie-Hélène Luton, Department Director – High Voltage Substation Equipment

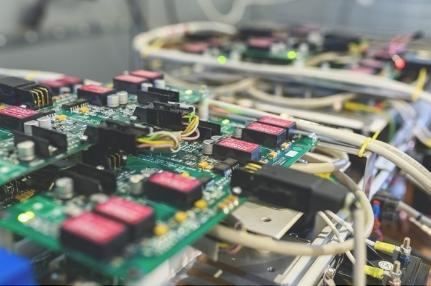

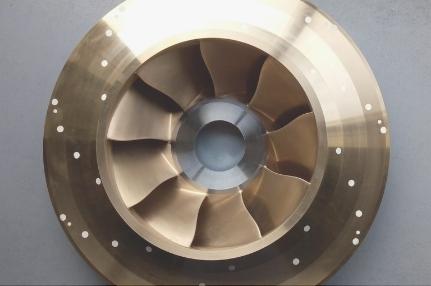

We develop substation technologies to respond to the constraints of future DC networks as well as those of current AC networks. This includes using circuit breakers to clear fault currents from meshed DC networks, as well as developing interconnection nodes to transfer energy. Our circuit breaker technologies and protection strategies are designed to reduce the cost of infrastructure and preserve the stability and availability of the network.

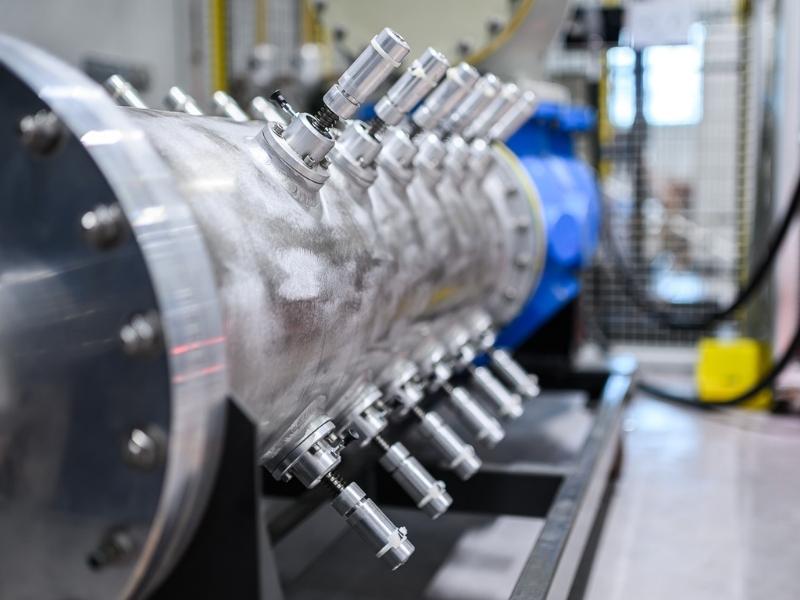

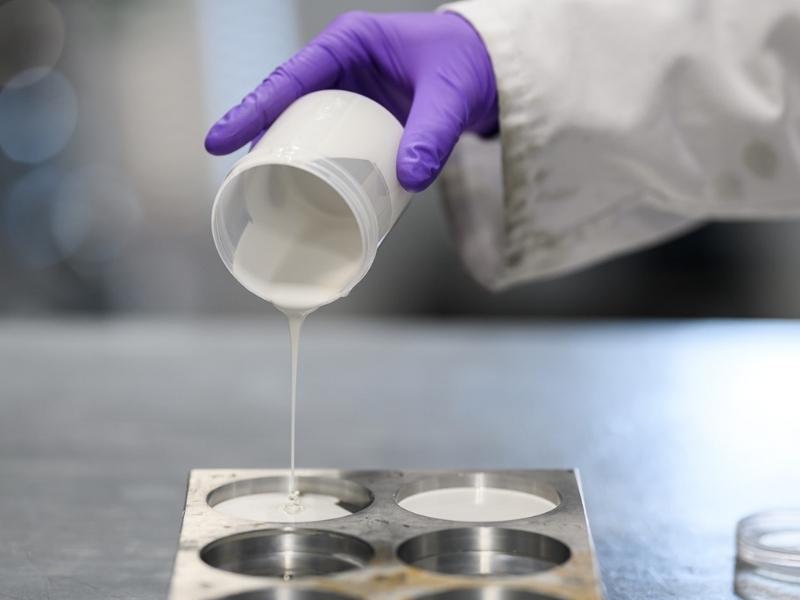

Gas-insulated switchgear is essential to networks, yet it is currently highly dependent on sulphur hexafluoride gas (SF6) – at the top of the list of greenhouse gasses – as the insulating medium. We study, model and optimise alternatives for gas-insulated switchgear. In addition, we research and implement new solid and gas insulation systems to provide enhanced electrical performance and resilience whilst maintaining low environmental impact.

To validate performance, we rely on SuperGrid Institute’s dielectric and power test laboratories. The characterisation platform enables us to define insulating material properties.

Our research projects include:

Recent publications

Influence of MMC control philosophies on Multi-Terminal HVDC Design and Expandability

the influence of different control philosophies for Modular Multi-level Converters on the design of MTDC grids’ control and protection is investigated and discussed.

Development of Frequency-dependant DC equivalent models for Multi-terminal DC grids

This paper highlights two DC grid equivalent models: a simple RLC model and a frequency-dependent reduced-order model.

Subsea smart hubs for floating wind

Subsea Smart Hubs project has been initiated with the aim of addressing new Inter-Array Cable system architectures for floating wind farms.