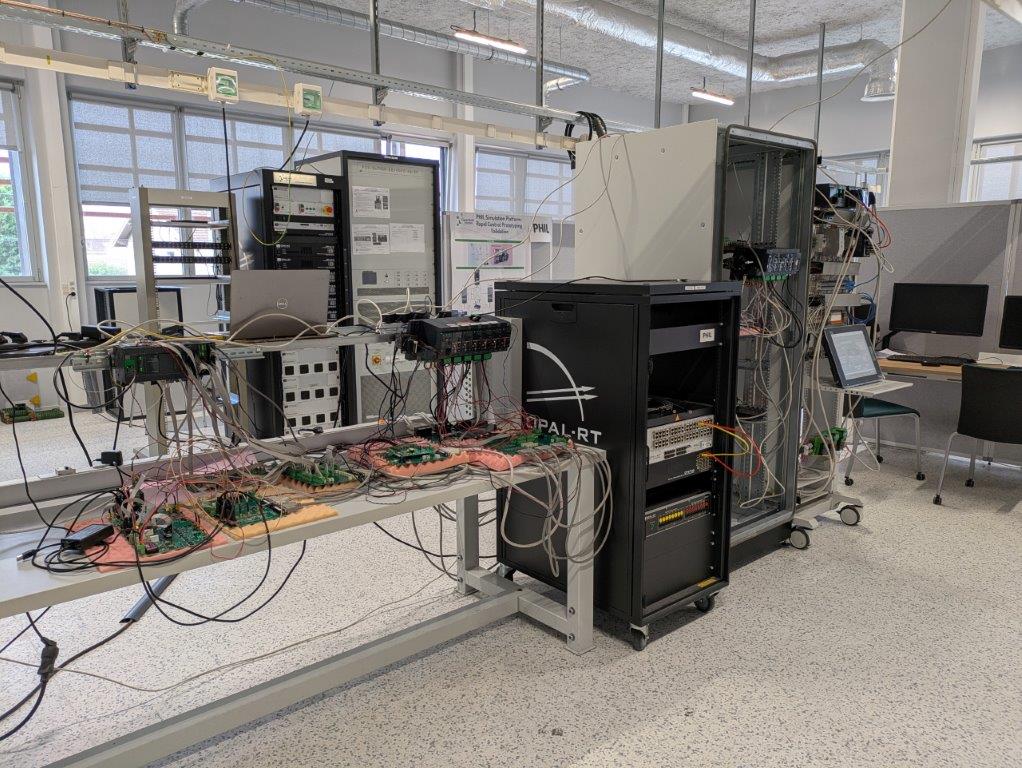

Real-time simulation platforms

MV & HV testing for your algorithms, controllers, mock-ups & converters

Hardware-in-the-loop (HIL) testing of electrical protection and control devices including:

- protection relays

- phasor measurement unit (PMU)

- intelligent electronic device (IED)

- converter control systems Modular Multi-level Converter (MMC)

- Supervisory Control and Data Acquisition (SCADA) systems

- Etc.

Power Hardware-in-the-loop (PHIL) tests of high-voltage equipment components or subsystems, scaled-down models of equipment.

Hardware-in-the-Loop

Our Hardware-in-the-Loop testing facilities offer you an excellent alternative to traditional testing methods.

With our state-of-the art software models, we recreate the electric grid and accurately reproduce the network’s dynamics. This allows us to test your algorithms’ and equipments’ interaction with control systems and other equipment in real-time.

We provide comprehensive closed-loop testing, negating the need for costly, dangerous tests on real systems.

Power Hardware-in-the-Loop

Our Power Hardware-in-the-Loop test platform allows you to test your devices under full power within the real-time simulation environment.

This in-depth testing allows you to validate your power equipment and understand its behaviour in real-life usage conditions, thanks to highly accurate and powerful simulations.

Building & maintaining a real-time digital twin of an MVDC demonstrator

SuperGrid Institute, successfully developed an advanced digital twin of a medium-voltage direct current (MVDC) demonstrator for linear photovoltaic power plants (OPHELIA project), addressing critical challenges in modern Power System Transmission.

Digital twins are a powerful tool to validate that a system and its equipment will function as expected. They can also be used to uncover unexpected results which in turn show how to improve equipment or troubleshoot during a network’s development phase. The value of this tool is now widely accepted but few real project demonstrators have been linked to a digital twin today.

Using the Hardware-in-the-Loop (HIL) platform, SuperGrid Institute’s team built a real-time digital twin of the MVDC OPHELIA demonstrator network.

The digital twin will run for 2 years (until 2028). During this period, it will be used to troubleshoot the day-to-day running of the network and will also provide valuable information about the digital twin tool itself, making it possible to develop more advanced versions in the future.

Added value