Supplying Power to HV (≥10kV) control and measurement boards: a challenge to overcome

New high-voltage power electronic converters and facilities for transmission grids tend to have multiple power switches at different floating potentials. Moreover, the trend goes towards the use of power switches with higher operating voltages (up to 10kV), in order to reduce the number of switches by system.

To develop reliable converters while taking advantage of these new power switches, special care should be given to the design of new control boards and their associated power supplies. It is challenging to power those control boards due to the high level of isolation required.

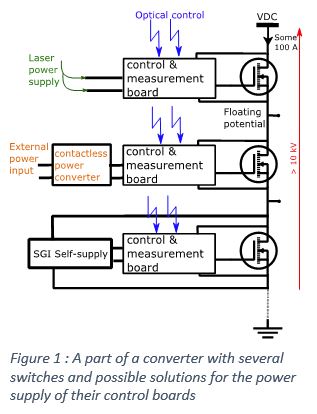

The control board is typically at the same potential as the switch. The supply system is in most cases a DC-DC circuit connected from one side to the ground of the full system and from the other side to the local ground of the gate-drive. In the aforementioned case, reaching the required isolation is a challenge in HVDC applications.

Contactless solutions exists in the literature, such as loop wire power supply [1, 2], but they are not adapted to the threshold limit of isolation needed (more than tens of kV). Additionally, the laser power method [3, 4] can’t fulfil the power supply demand for switches rated for high currents (some 100A) and operating at high frequencies (some 10 kHz). A thesis work in progress, in P3.4 SuperGrid’s team, is related to the calculation and design of power supply solutions subjected to these high potentials.

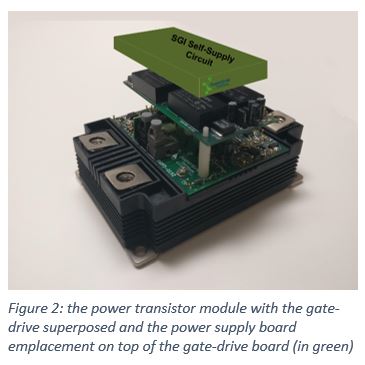

During this work, a first prototype circuit was designed and successfully tested. This circuit is placed at the same potential as that of the switch, and allows the control board to be supplied while the switch is off by harvesting energy from its polarized voltage. It is the called “self-supply circuit”. It has a very low component count and is able to supply a control board of a switch of low rated current (corresponding consumption up to 2W).

But in most cases, when it is needed to switch hundreds of Amperes, the control board consumption is higher and closer to ~ 20W. Furthermore, this higher consumption level will allow the control boards, and any nearby sensor, to be supplied if needed.

DC-DC self-supply circuit specification:

- Output supply power : 20W

- Input range (with regard to local ground) : 200V to 2kV,

- Regulated 24V output,

- Self-start-up feature.

A self-start-up means that the system needs low input voltage to be able to generate a significant output power. This feature allows the control and measurement board to be supplied, and send a status report of the component before reaching the nominal voltage in the full system.

Solving the HV isolation constraint (between ground and local ground), the proposed self-supply solution can deliver the needed power to the control board. At the end of this thesis, it is expected to test the board in situ. Looking ahead, an upgrade to the system could involve the integration of the self-supply, the control, and measurement system on the same monolithic board.